Mechanical Engineering Technology

MET Program Mission

The mission of the Mechanical Engineering Technology Program is to provide a Bachelor of Science degree to students seeking an education leading to a career in the engineering or manufacturing fields. The secondary mission is to maintain a healthy relationship of education excellence, faculty research, student involvement, and corresponding contact with the mechanical engineering industry to provide mutual support for our academic, industry, and extended community.

Courses Required for Entrance into the MET Program

Mechanical Engineering Technology Program Goals

- To provide a Bachelor of Science degree in a four-year program that enables students to find employment related to Mechanical Engineering Technology.

- To continue to improve the quality of our program through constant feedback and modification.

- To continue to improve the efficacy of our program by recruiting students of diverse backgrounds and interests.

- To continue to improve and evolve our courses and offerings to respond to our state‘s needs and student‘s interests.

- To continue to improve our program by building mutually beneficial partnerships with industry, professional groups and other entities, with a focus on student involvement.

Mechanical Engineering Technology Program Capabilities

The MET Program has faculty members specializing in areas including mechanical systems, manufacturing, composites, castings, heat transfer and energy methods. Please see our faculty list for more specifics. Our labs focus on foundry, machining, composites, production technology, energy conversion, and systems. Service work is not done, but industry support is prominent and students have access to these resources as the classes are enacted. Samples of specific resources are listed below:

The CWU Foundry is an industrial-grade green sand system (2 cubic yards) with flasks up to 12x18”. There are two furnaces (gas and induction) with 30’ of pour line under the crane. The pattern shop has a new CNC with various support materials. Our sand analyses include distribution, compaction, and moisture.

The CWU Materials Lab has testing equipment for tensile, impact, fatigue, hardness, and creep. Process equipment includes three injection molders, roto-molding, drape-molding, hot-press and vacuum. The composites lay-up area has a 10-15’ stainless steel table, three reusable vacuum bags, an oven and all support materials (e.g. manifolds, bag materials, reinforcements, release plies, glues, pre-pregs).

The machining lab has three industrial-grade 3-axis CNC’s (Miltronics) and two CNC lathes with much other manual equipment (e.g. horizontal saw, knee-mills, grinders).

The woods lab has a Techno CNC router (4x8’) and all necessary equipment to produce cabinets (e.g. planer, jointer, sander, pin-router).

The fluids/energy lab has a suite of student equipment to interact with appropriate concepts such as wind tunnel, frictionless dynamics, and engines.

The power lab has hydraulics trainers, power stations, CNC plasma cutter (4x4’), a variety of welding tools and many forming/punch tools.

CWU News

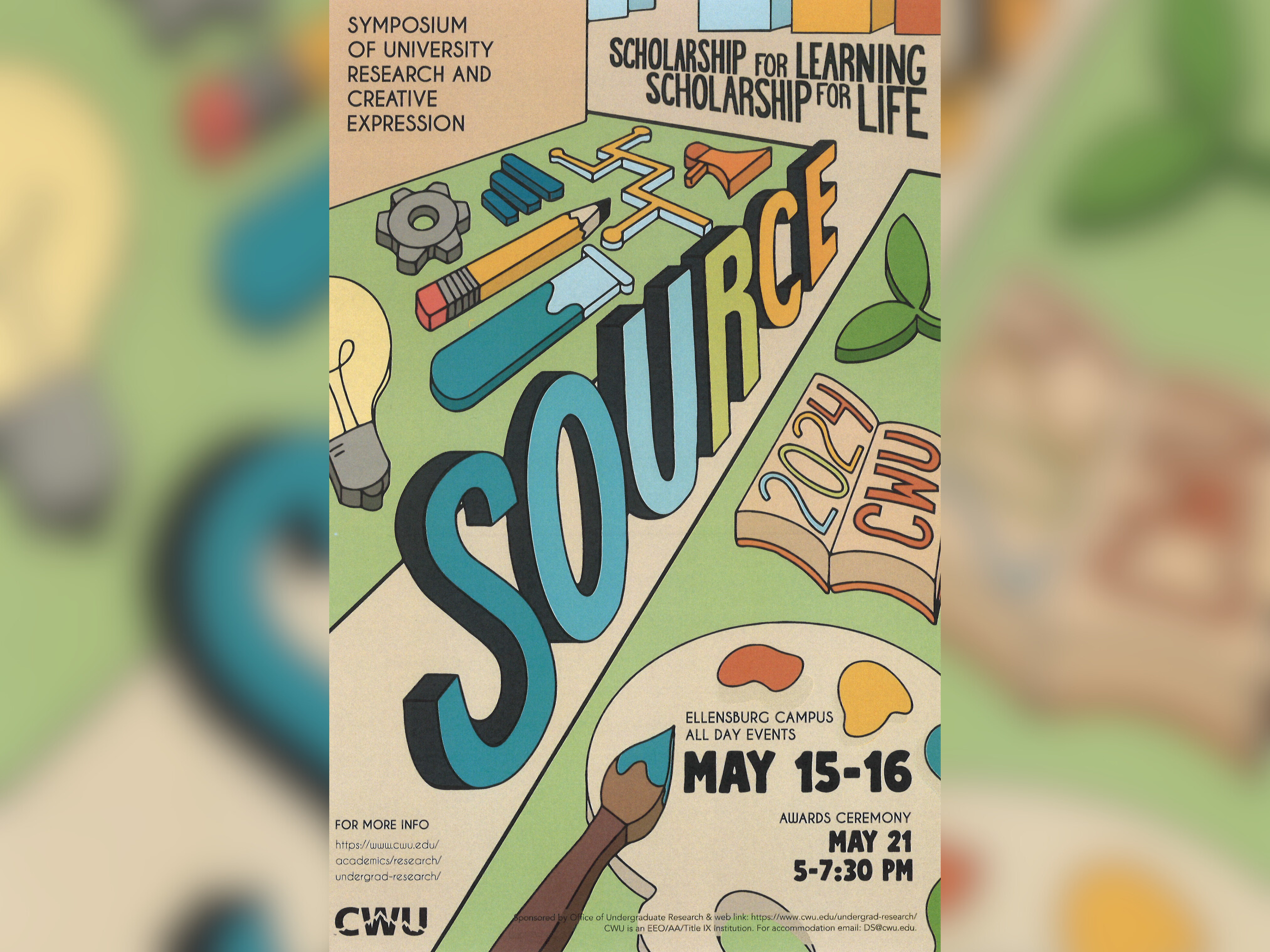

CWU to highlight student research at next week’s SOURCE conference

May 8, 2024

by Rune Torgersen

CWU Theatre and Film to present ‘Footloose’ the next two weekends

May 8, 2024

by University Relations