CWU Sustainability

CWU's Waste Heat Recovery System

CWU's Waste Heat Recovery System at the Steam Plant

In an effort to improve energy efficiency on campus, Central Washington University (CWU) installed a heat exchange system that captures waste heat. CWU’s campus is mainly heated with steam produced from natural gas-powered boilers at the steam plant. With the captured waste heat, Samuelson, Discovery Hall, and the future Health Sciences building can be heated without extra energy production.

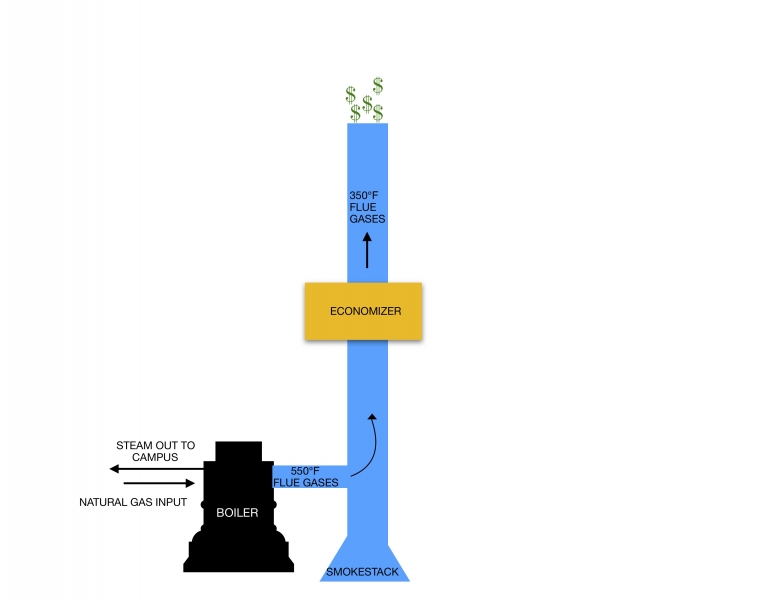

Overview of CWU's Steam Plant

- The steam plant has four natural gas-powered boilers.

- The boilers heat steam that gets directed to campus buildings by forced air fans. The majority of buildings at CWU are heated by the steam plant.

- Along with the steam, the boilers also produce 350 F flue gases that historically entered the atmosphere through smokestacks.

A model of CWU’s boiler system without the addition of the CONDEX system.

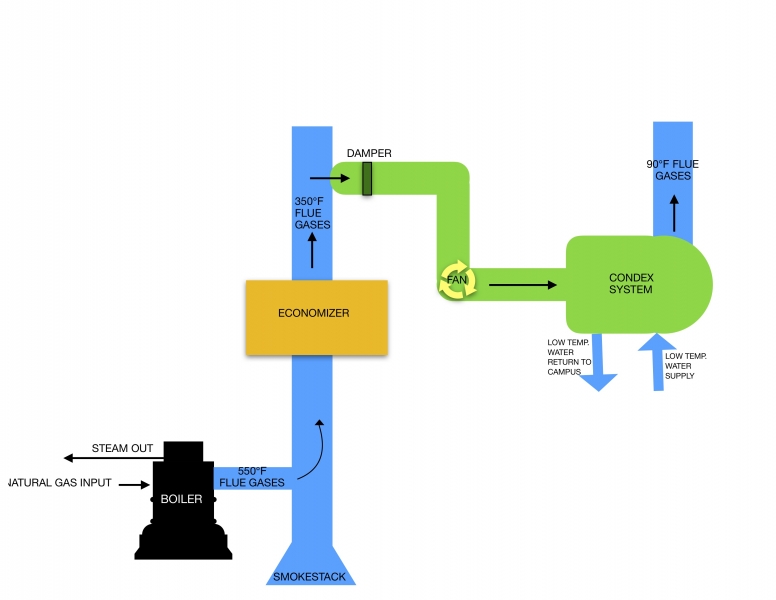

Improved Energy Efficiency by Adding a Heat Exchanger

- In June of 2015, CWU added a condensing economizer (CONDEX system) that captures the waste heat produced from the boilers' flue gases.

- The recovered heat allows Samuelson and Discovery Hall (261,036 combined square feet) to be heated without burning additional natural gas, resulting in an 8% efficiency improvement.

- The new Health Sciences building will also be heated with recovered waste heat upon its completion.

A model of CWU’s boiler system with the addition of the CONDEX system.

Glossary

Flue gases: mixture of products of combustion passing through the smokestack.

Supply control dampers: automated valves within the flue pipe that stops or regulates steam flow.

Economizer: used to capture heat from flue gases to preheat incoming boiler feed water, reducing the firing rate of the boiler.

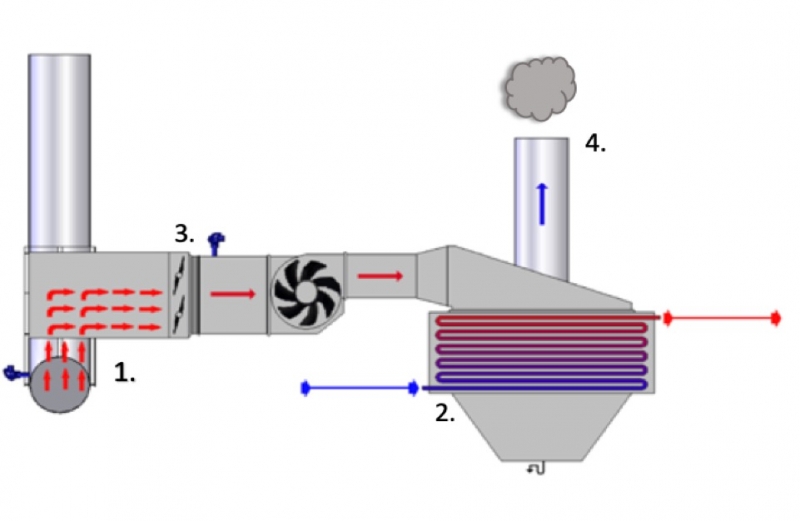

How does the CONDEX system work?

- Flue gases are drawn off of the boiler stacks by fans, which push them through the CONDEX heat exchanger

- The gases are then cooled by glycol to the point where water vapor can condense, releasing the heat it took to vaporize initially

- As the boilers load changes, the supply control dampers open and close to capture all available flue gases

- The remaining 90° F gases leave the heat exchanger and are discharged to the atmosphere by a separate stack.

A model of the CONDEX heat exchanger

This new innovation allows CWU to:

- Prevent burning additional natural gas

- Reduce greenhouse gas emissions

- Save money

- Recover usable water from flue gas condensation

- Enhance sustainability on campus

CWU News

Online Master’s of Education program now offers special education endorsement

May 15, 2024

by Rune Torgersen

Lenny Price brings Detroit perspective to CWU Jazz

May 15, 2024

by University Relations